Common types of pipe expansion joints

Pipe expansion joints reduce vibration, suppress sound transmission in piping systems, and prevent damage caused by excessive pipe movement. It is very important to choose the right pipe expansion joint. There are many types of pipe expansion joints, how can we distinguish them? In this article, we will classify the pipe expansion joints according to their production material and shape.

There are four main types of pipe expansion joints according to the materials used to make them

- Rubber Expansion Joint

Rubber expansion joints can also be referred to as non-metallic expansion joints. It helps to solve the pressure, thermal growth, movement, vibration or stress in the piping system. Rubber expansion joints can be made from many different types of rubber materials to meet the different needs of customers. They are also frequently used in air conditioning, ventilation and cooling systems, petrochemical and industrial applications.

- Metal Expansion Joint

Metal expansion joints can also be called metallic expansion joints, metal pipe expansion joints, metal joints, and metal pipeline expansion joints. The metal bellows is the main body of the metal expansion joint. The bellows can be made of different metals depending on the customer’s needs. It can accommodate axial, longitudinal and angular movements of pipes, conduits and vessels.

- Fabric Expansion Joint

Fabric expansion joints enable industrial piping systems and fan/blower connections to absorb thermal growth, isolate vibration and noise, and allow for misaligned operation. With their large action in each space, small spring rate and wide temperature range give them advantages that other types of joints do not have. As a result, they help a variety of industries, including power, petrochemical, pulp and paper, and many other industrial facilities.

- PTFE Expansion Joint

PTFE expansion joints are made from the synthetic material polytetrafluoroethylene, an inactive material that is widely used in chemical manufacturing pipelines as a protective agent against corrosive substances. It is the ideal solution for industrial piping applications that can be affected by erosive or corrosive environments.

There are four main types of pipe expansion joints according to the structure.

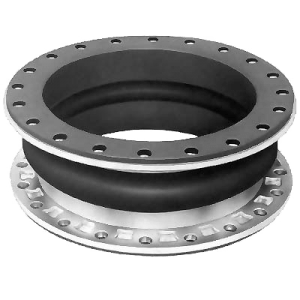

- Double Sphere Expansion Joint

Double Sphere Expansion Joint is also called double arch joint. With its unique design, novel structure and good sealing, it solves the problem of pipeline bursting and damage to pipeline connection equipment caused by thermal expansion and contraction, effectively improving the life cycle of pipelines and the protection of equipment.

- Single Sphere Expansion Joint

Single Sphere Rubber Joints have good comprehensive performance and are mainly used for lifting and conveying raw water and sewage, feed water and cooling circulating water of thermal power plants, metallurgical industry, condensate, pipeline transportation of chemical substances in chemical industry, cooling in petrochemical industry, dilution and flexible connection between long and short distance pipelines in other industries.

- Wide Sphere Expansion Joint

Wide Arch Expansion Joint is also often called Full face type rubber expansion joints . It is molded wide arch designed, completed with full face rubber flanges, with no embedded metal ring. All rubber impregnated construction will extend service life.

- Threaded Union Expansion Joint

Threaded union rubber joints is also known as union double sphere rubber joints. The common application mediums are as follows, for example, transporting air with -15°C -80 °C, compressed air, water, sea water, oil, acid and alkali etc.

Explore More: 7 Types of Rubber Expansion Joints

JOINTIB is a leading rubber expansion joints manufacturer and supplier designing cost effective joints. JOINTIB is always glad to assist and help on all questions of Rubber Expansion Joints. You can contact us by filling out a form on our website or writing email to sales@jointib.com

Send Your Question

Recent Post

-

The Rubber Expansion Joint Market in 2026: Trends, Challenges, and Opportunities

-

Rubber Joint Applications in the Water Treatment Industry

-

Has the price of rubber expansion joints in China increased?

-

Rubber Expansion Joint Manufacturing Process in China

-

Chinese Rubber Joint Manufacturer Establishes Strong Foothold in Australian Market

PEW

Hi, I’m the author of this post, and I have been in this field for more than 10 years. If you want to get more info about industrial pipe rubber expansion joints, feel free to ask me any questions.