7 Types of Rubber Expansion Joints

With its excellent performance, Rubber Expansion Joints are used in many fields, such as water and wastewater, pulp and paper, chemical processing, air conditioning, heating and ventilation systems, mining, metals and pumping etc.

There are different ways to classify rubber joints, such as material, structure, etc. For this article, Rubber Expansion joints can be divided into 7 types according to the structure.

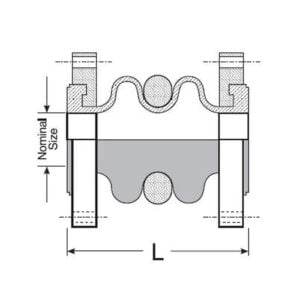

Double Sphere Expansion Joint is also called double arch joint. With its unique design, novel structure and good sealing, it solves the problem of pipeline bursting and damage to pipeline connection equipment caused by thermal expansion and contraction, effectively improving the life cycle of pipelines and the protection of equipment.

Advantages:

- Absorption of Directional Movement

- Absorption of Vibration, Noise and Shock

- Compensation for Misalignment

- Lighter Weight

- No gaskets required; integrally rubber flanged design

Disdvantages:

- The two spheres are easily chipped at the junction

- Smaller pressure resistance compared to but spheres

Applications:

Double Sphere Expansion Joint has good comprehensive performance, so it is widely used in chemical industry, construction, water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, plumbing, fire-fighting, electric power and other basic projects.

Single Sphere Rubber Joints have good comprehensive performance and are mainly used for lifting and conveying raw water and sewage, feed water and cooling circulating water of thermal power plants, metallurgical industry, condensate, pipeline transportation of chemical substances in chemical industry, cooling in petrochemical industry, dilution and flexible connection between long and short distance pipelines in other industries.

Advantages:

- Economical, any flange standards available

- Solid floating flanges, easy to install

- No gaskets required

- Protects hydraulic equipment for long-term use

Disdvantages:

- Short lengths

- Small displacement in angular direction

Applications:

Single Sphere Expansion Joint It is especially suitable for use in various water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, plumbing, fire-fighting, electric power and other basic engineering pipelines.

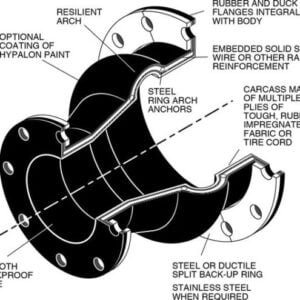

3. Wide Arch Expansion Joint

Wide Arch Expansion Joint is also often called Full face type rubber expansion joints . It is molded wide arch designed, completed with full face rubber flanges, with no embedded metal ring. All rubber impregnated construction will extend service life.

Advantages:

- Wide flowing arch design

- Absorbs vibration, noise and shock

- integrally rubber flanged design

- No gaskets required

Disdvantages:

- Short lengths

- This flange/body angle is difficult to form

Applications:

Wide Arch Expansion Joint is double wide-arch products, specifically constructed to reduce or eliminate common occurrences such as noise and vibration, misalignment/offset, or turbulence. It is appropriate for a wide variety of industrial applications, and are available in open arch and filled arch configurations.

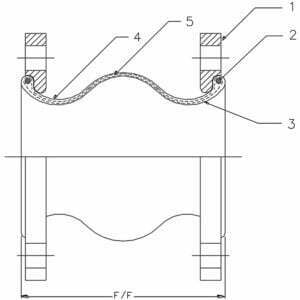

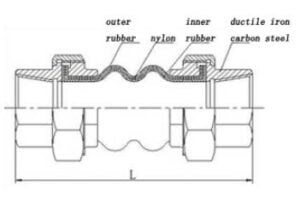

4. Threaded Union Expansion Joint

Threaded union rubber joints is also known as union double sphere rubber joints. The common application mediums are as follows, for example, transporting air with -15°C -80 °C, compressed air, water, sea water, oil, acid and alkali etc.

Advantages:

- Compensate for misalignment/offset

- Improve the flow circulation and avoid the bellow deformation

- Absorbs thermal expansion and shock

Disdvantages:

- They must be replaced if damaged.

- Require that the system be shut down when a failure occurs.

Applications:

Threaded union rubber joint can bu used in any lower temperature systems requiring thermal expansion, settlement, or other movement where chemically compatible.

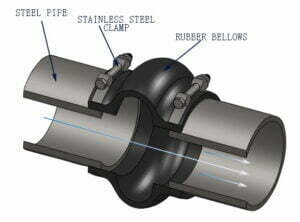

5. Slip-On Type Expansion Joint

Slip-on type pipe expansion joints are used when the primary problem is a large axial movement. It is convenient to set the two ends of the clamped rubber joint on the pipe to be connected, and the rubber joint is fixed to the pipe through the stainless steel clamp.

Advantages:

- Save flanges and bolts

- No need to turn the edge at the pipe mouth

- Simplifies installation and maintenance work

- Corrosion resistance

Disdvantages:

- Without the kind of high pressure performance of flanged rubber joints.

- The maximum pressure of clamped rubber joints is not more than 3~5kg, if it is too big, choose flanged rubber joints.

Applications:

Slip-On Type Expansion Joint is mainly used for lifting and conveying raw water and sewage, feed water and cooling circulating water of thermal power plants, metallurgical industry, condensate, pipeline conveying of chemical substances in chemical industry, etc.

6. Concentric Reducers Expansion Joint

Concentric Reducers Expansion Joint is most commonly used as a pump or equipment connector. It can also be used as an expansion joint if EJMA guidelines are followed. Control rods are optional but recommended.

Advantages:

- Absorbs vibration, noise and shock

- It handles movement in all directions

- Provides expansion joint and reduces to accommodate a pipe size change

- Stocked in standard lengths, with specials avaialble

Disdvantages:

- The taper in the expansion joint should never exceed 20 degrees for concentric

- Inconvenient maintenance

- The combined length of a standard steel pipe reducer and a standard straight rubber expansion joint is too long to be implemented in the piping system

- .

Applications:

Concentric Reducers Expansion Joint is mainly used for Flexible pump and other equipment connectors where a change in pipe size from the equipment.

7. Eccentric Reducers Expansion Joint

Eccentric Reducers Expansion Joint is constructed of high strength fabric and elastomer, and the flanges are integral with the body and utilize metal backing rings.

Advantages:

- Absorbs vibration, noise and shock

- Provides expansion joint and reduces to accommodate a pipe size change

- Stocked in standard lengths, with specials avaialble

Disdvantages:

- The taper in the expansion joint should never exceed 10 degrees for eccentric reducers

- Inconvenient maintenance

- The combined length of a standard steel pipe reducer and a standard straight rubber expansion joint is too long to be implemented in the piping system.

Applications:

Eccentric Reducers Expansion Joint is mainly used for Flexible pump and other equipment connectors where a change in pipe size from the equipment.

I have spent a week to compile a catalog PDF of Pipe Rubber Expansion joints, which includes all types of Rubber Bellow Expansion joints specifications, categories, pictures, advantages, and so on. You can click the button below to Download Rubber Expansion Joints Catalogue PDF 2022. If you have more questions, you can contact me.

Send Your Question

Recent Post

-

The Rubber Expansion Joint Market in 2026: Trends, Challenges, and Opportunities

-

Rubber Joint Applications in the Water Treatment Industry

-

Has the price of rubber expansion joints in China increased?

-

Rubber Expansion Joint Manufacturing Process in China

-

Chinese Rubber Joint Manufacturer Establishes Strong Foothold in Australian Market

PEW

Hi, I’m the author of this post, and I have been in this field for more than 10 years. If you want to get more info about industrial pipe expansion joints, feel free to ask me any questions.