Rubber Expansion Joint

JOINTIB stocks and distributes a comprehensive range of rubber expansion joints for use in many tough, demanding industrial applications such as water and wastewater, pulp and paper, chemical processing, air conditioning, heating and ventilation systems, mining, metals and pumping applications.

All uploads are secure and confidential

Hi, I’m Pew from JOINTIB. Let me guide you through this page. Our company has been working so hard for more than 20 years to perfect the process of manufacturing Rubber Expansion Joint. Click the table of contents to know more about the products.

What is Rubber Expansion Joint?

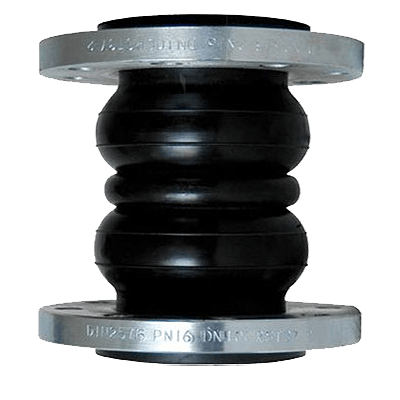

Rubber expansion joint is also called pipe rubber expansion joint, or rubber bellow expansion joint.

It is a flexible connector fabricated of natural and/or synthetic elastomers and fabric, if necessary, internal metallic reinforcements designed to provide stress relief in piping systems due to thermal movements and mechanical vibration.

Rubber expansion joints offer flexibility allowing concurrent movements, isolation of vibration, reduction of noise, resistance to abrasion and chemical erosion within fluid systems.

Why use Rubber Expansion Joint?

Reduce Mechanical Noise

It dampens sound transmission with their rubber to steel interface.

Reduce Vibration

It is important to prevent unbalanced forces building up to a level where they can damage a fluid system.

Improve Thermal Stability

It may use PTFE and FEP liners within the joint body. When fluoroplastics are used in rubber expansion joints this results in better thermal stability.

Absorb Movement

It can routinely manage the resulting lateral, torsional and angular movements whilst strategically located rubber expansion joints can mitigate thermal expansion and contraction movements.

Resistant Abrasion/Erosion

It is made from a wide variety of natural, synthetic, and special purpose elastomers and fabrics to meet challenging operating conditions.

Easy To Install

The vulcanized rubber and fabric flanges of elastomeric expansion joints are integrated and therefore do not require additional gaskets.

Types of Rubber Expansion Joint

Double Sphere Expansion Joint

Supply Range: DN25mm to DN1000mm

Wide Arch expansion Joint

Supply Range: DN40mm to DN300mm

Threaded Union expansion Joint

Supply Range: DN15mm to DN80mm

Slip-On Type Expansion Joint

Supply Range: DN50mm to DN500mm

Concentric Reducers Expansion Joint

Supply Range: DN25mm to DN3000mm

Eccentric Reducers Expansion Joint

Supply Range: DN25mm to DN3000mm

1. We can source any other material or type on request, but quotes take up to 48 hours.

2. All you need to know the detailed information of types of rubber expanion joint, click here

Parts of Rubber Expansion Joint

Material: EPDM/NBR/Hypalon

Function: A protective, leak-proof lining tube that extends through the bore to the outside edges of the flanges to eliminate the possibility of the fluids penetrating the carcass and weakening the fabric.

Material: Ductile Iron/Carbon Steel/SS304/ss316

Function: A synthetic or natural fabric between the tube and cover that flexibly supports the expansion joint for movement or pressure.

Material: Mild Steel

Function: Solid rings or wire embedded in the carcass which strengthen the expansion joint to withstand high pressure or vacuum.

Material: EPDM/NBR/Hypalon

Function: A synthetic or natural fabric between the tube and cover that flexibly supports the expansion joint for movement or pressure.

Material: Nylon

Function: The body of the expansion joint consisting of fabric and / or interior metal reinforcement.

Industry Applications of Rubber Expansion Joint

Water & Wastewater

Marine

Chemical

Food Processing

HVAC

Power

Pulp & Paper

Mining

Considerations When Buying Rubber Expansion Joint

In order to buy the right Rubber Expansion Joint, there are many factors to consider.

Working Conditions

Determine the use of the rubber joint in the equipment or device and determine the working conditions of the product: applicable medium, working pressure, working temperature, etc.

Connection Method

Determine the nominal diameter of the pipe connected to the rubber joint and the connection method: flange, thread, welding, etc.

Choose Type

Choose the type of rubber joint: double sphere joint, single sphere joint, multi-sphere joint, safety joint, etc.

Operation Method

Determine the way to operate the flexible joint: manual, electric, electromagnetic, pneumatic or hydraulic, electrical linkage or electro-hydraulic linkage, etc.

Select Material

According to the medium, working pressure and temperature of the pipeline, determine the material of the shell and inner parts of the rubber joint: rubber, gray cast iron, cast iron, ductile iron, carbon steel, alloy steel, stainless acid-resistant steel, copper alloy, etc.

Determine Parameters

Determine the parameters of rubber joints: For automatic rubber joints, first determine the allowable flow resistance, discharge capacity, back pressure, etc. according to different needs, and then determine the nominal diameter of the pipe and the diameter of the valve seat hole.

How We Work Together

Our ordering process

Receive instant quote

Confirm specs

Production

Quality control

Delivery

How We Work Together

Our ordering process

Receive instant quote

Confirm specs

Production

Quality control

Delivery

Things you Need to Know

To save you from worries, here are some facts you need to know about our supplies:

Unfortunately, no. You will have to pay a small fee for shipping Rubber Expansion Joint.

Always a pre-production sample before mass production; Always final Inspection before shipment;

Of course we do.

By sea or air. Normally 7 to 14 Days for delivery, according to your order quantity.

Carton cases inside, export wooden cases outside.

Contact JOINTIB to Start Your Business

Have a look at how some of our clients perceive our goods and services:

It was a very enjoyable experience work with JOINTIB company. To get good product price make us competitive in market. The JOINTIB people have high responsebility for quality assurances. What really turned me over was the JOINTIB’s ability to understand how everything works.

We have worked with JOINTIB since 2017. As our requirements have changed over time, they are patient and professional to solve all the problems. I was pleased to work with them, and JOINTIB has always kept in step with its innovation and product development.

Excellent customer service! More products I have ordered products from JOINTIB for clients. All employees of the company have maintained a helpful and courteous attitude and are willing to provide any assistance. Our cooperation is always very pleasant. JOINTIB company high quality products, timely delivery and amazing customer service is always worthy of my trust!