Leading Manufacturers of Rubber Expansion Joints in 2025

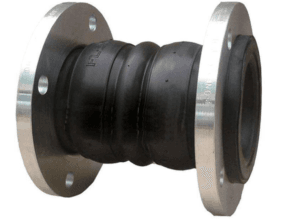

Rubber expansion joints, also known as rubber bellows or flexible connectors, are critical components in piping systems across industries such as oil and gas, water treatment, chemical processing, and HVAC. These joints compensate for thermal expansion, absorb vibrations, and reduce noise, ensuring the longevity and efficiency of infrastructure. Several manufacturers have risen to global prominence by combining advanced engineering, material innovation, and rigorous quality standards. Here’s an overview of some of the most renowned rubber expansion joint manufacturers worldwide.

1. Proco Industries, Inc.

Headquartered in the United States, Proco has been a trailblazer in rubber expansion joint technology since 1978. The company specializes in high-performance elastomeric joints designed for extreme conditions, including high-pressure and high-temperature applications. Proco’s products are widely used in the oil and gas sector, particularly in offshore drilling and pipeline systems. Their patented Proco-SAFE® line incorporates safety restraints to prevent catastrophic failures, earning them a reputation for reliability in hazardous environments. With a global network spanning North America, Asia-Pacific, and the Middle East, Proco remains a leader in innovation and customer-centric solutions.

2. Trelleborg AB

A Swedish multinational, Trelleborg is a heavyweight in engineered polymer solutions. Its Vibracoustic and Sealing Profiles divisions produce premium rubber expansion joints tailored for industries like marine, energy, and aerospace. Trelleborg’s joints are celebrated for their chemical resistance and durability, leveraging proprietary materials such as EPDM, NBR, and FKM elastomers. The company’s R&D focus on sustainability has led to eco-friendly products, including joints made from recycled rubber. With manufacturing hubs in Europe, the Americas, and Asia, Trelleborg combines global reach with localized expertise.

3. ContiTech AG (Continental Group)

Germany’s ContiTech, part of the Continental Group, excels in rubber and plastics technology. Its expansion joints are integral to industrial fluid systems, particularly in power plants and chemical processing facilities. ContiTech’s MULTITECH® series features multi-layered fabric-reinforced joints capable of handling aggressive media and extreme pressures. The company’s emphasis on digitalization includes IoT-enabled joints that monitor wear and stress in real time, aligning with Industry 4.0 trends. ContiTech’s engineering prowess and adherence to ISO 9001 standards solidify its position as a trusted partner for complex projects.

4. Goodall Rubber Company

A U.S.-based family-owned enterprise since 1921, Goodall Rubber Company is synonymous with customization. They manufacture joints for niche applications, including nuclear facilities, mining, and wastewater treatment. Goodall’s Ultra-Flex® line incorporates PTFE liners for superior chemical resistance, while their Gator-Flex® series addresses abrasive slurry transport. The company’s agile production and rapid prototyping capabilities make it a go-to for bespoke solutions, earning certifications from ASME and API.

5. Flexicraft Industries

Specializing in corrosion-resistant systems, Flexicraft Industries (USA) produces rubber expansion joints for chemical and petrochemical plants. Their Chem-Flex® joints use advanced fluoropolymer coatings to withstand acids and solvents. Flexicraft also prioritizes environmental compliance, offering joints that meet EPA and REACH regulations. Their global distribution network ensures timely delivery, supported by 24/7 technical assistance.

6. JOINTIB (China)

As Asia’s manufacturing hub grows, JOINTIB has emerged as a key player. The Chinese manufacturer offers cost-effective rubber joints without compromising quality, serving industries like shipbuilding and HVAC. Their products meet CE and ISO standards, combining affordability with performance, making them competitive in emerging markets.

Innovation and Sustainability

Leading manufacturers invest heavily in R&D to enhance joint longevity and eco-friendliness. Bio-based elastomers, recyclable materials, and energy-efficient production methods are now industry priorities. Additionally, collaborations with end-users ensure products evolve with changing industrial demand

JOINTIB has been providing cost-effective and durable rubber expansion joints and duckbill check valves . Our products are very resistant to corrosion and breakage under harsh conditions. For more information about our products, and to inquire about pricing and availability, please contact us today. You can contact us by filling out a form on our website or writing email to sales@jointib.com

Send Your Question

Recent Post

-

The Rubber Expansion Joint Market in 2026: Trends, Challenges, and Opportunities

-

Rubber Joint Applications in the Water Treatment Industry

-

Has the price of rubber expansion joints in China increased?

-

Rubber Expansion Joint Manufacturing Process in China

-

Chinese Rubber Joint Manufacturer Establishes Strong Foothold in Australian Market

PEW

Hi, I’m the author of this post, and I have been in this field for more than 10 years. If you want to get more info about industrial pipe rubber expansion joints, feel free to ask me any questions.